Postojeća pumpa - Vodosnadbevanje

Zamenska pumpa List sa zamenskim informacijama

Komentar

Informacije o proizvodu

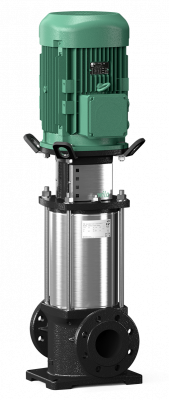

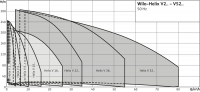

Helix FIRST V 1605

Posebne karakteristike/prednosti proizvoda

- Laserski zavarena, optimizovana 2D/3D hidraulika optimizovanog stepena korisnog dejstva

- Radna kola otporna na koroziju, vodeća kola i stepenasto kućište

- Hidraulika sa optimizacijom protoka i uklanjanjem gasova

- Ojačano kućište pumpe sa optimizovanim zapreminskim protokom i NPSH-om

- Štedi mesto i pogodna za održavanje, zahvaljujući kompaktnoj konstrukciji

- Izuzetno snažna zaštita spojnice

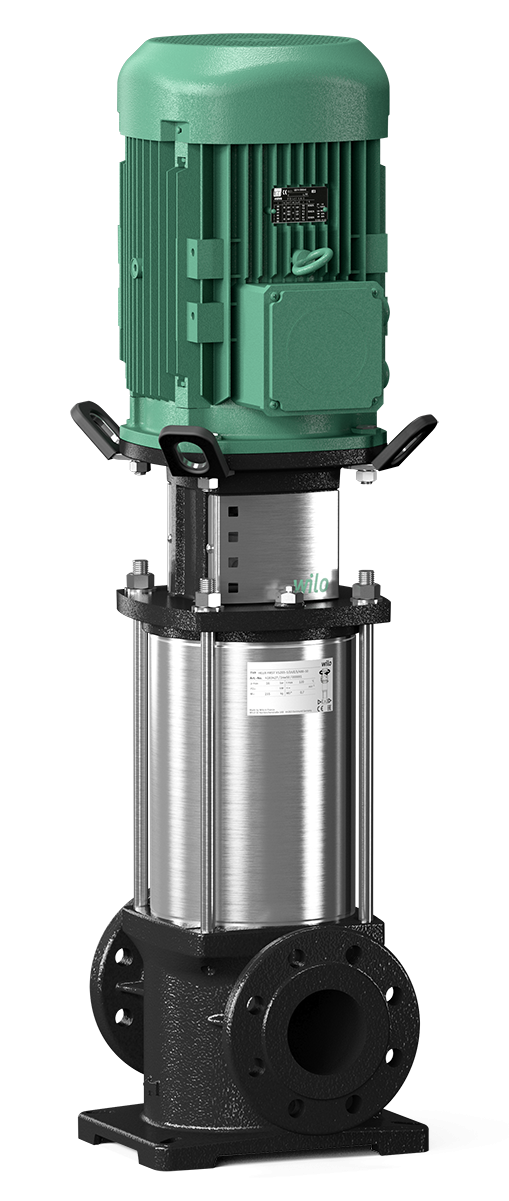

Višestepena centrifugalna pumpa visokog pritiska, visoke efikasnosti, sa normalnim usisavanjem, vertikalni model sa inlajn priključcima.

Primena

- Vodosnabdevanje i povišenje pritiska

- Industrijska cirkulaciona postrojenja

- Procesna voda

- Zatvoreni kružni tokovi hlađenja

- Protivpožarni sistemi

- Postrojenja za pranje

- Navodnjavanje

- Radna kola otporna na koroziju, vodeća kola i stepenasto kućište

- Višestepena centrifugalna pumpa visokog pritiska Helix FIRST V

- Uputstvo za ugradnju i upotrebu

- Helix FIRST V 2 – 16 (verzija PN16 sa ovalnim prirubnicama): Kontraprirubnice od sivog liva sa odgovarajućim zavrtnjima, navrtkama i zaptivačima

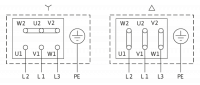

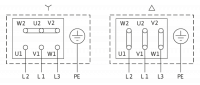

- Električni priključak: 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/400 V; Δ/Y

- > 4 kW 400 V/690 V; Δ/Y

- Temperaturno područje fluida: -20 °C do +120 °C

- Maks. radni pritisak: 16, 25 ili 30 bara

- Maks. pritisak dotoka 10 bara

- Klasa zaštite: IP55

- Maks. temperatura okoline: -15 °C do +50 °C

- Helix FIRST V 2 – 16: PN 16 sa ovalnim prirubnicama, PN 25/PN 40 sa okruglim prirubnicama u skladu sa ISO 2531 i ISO 7005

- Helix FIRSTV 22 – 52: PN 16/PN 25/PN 40 sa okruglim prirubnicama u skladu sa ISO 2531 i ISO 7005

- Radna kola, stepenasto kućište i rotori od nerđajućeg čelika 1.4307 (AISI 304L)

- Kućište pumpe od EN-GJL-250 sa KTL-prevlakom

- Vratilo od nerđajućeg čelika 1.4057 (AISI 304L)

- Čaura ispod mehaničkog zaptivača 1.4404 (AISI 316L)

- O-prsten od EPDM

- Obložena cev od nerđajućeg čelika 1.4301 (AISI 304)

- Pumpe se na zahtev mogu prilagoditi određenim uslovima (npr. zaštita motora, stepen iskorišćenja motora IE4, VdS-sertifikovane Wilo-Helix-pumpe, ATEX, prošireno područje temperature okoline).

Zamenska pumpa List sa zamenskim informacijama

Komentar

Informacije o proizvodu

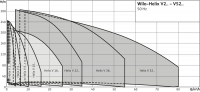

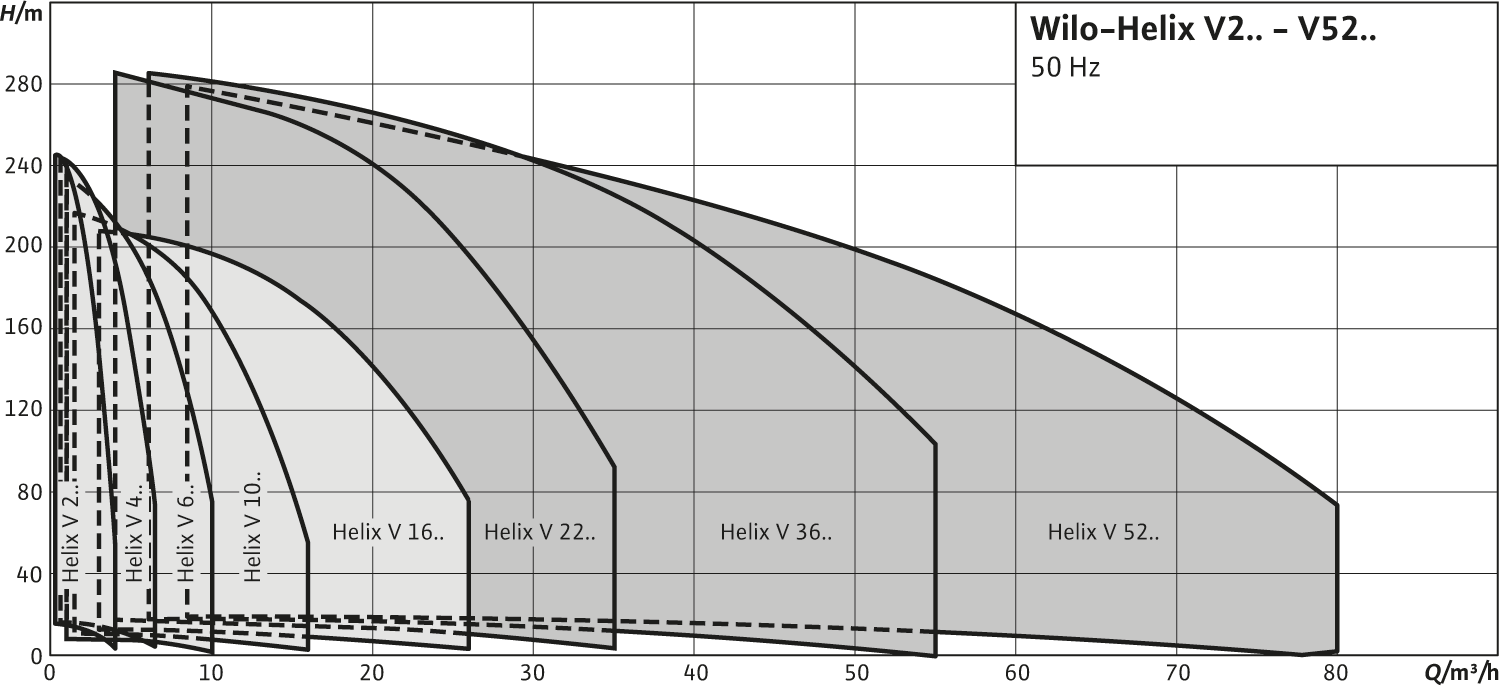

Helix V 1605-1/16/E/KS/400-50

Your advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

- Corrosion-resistant impellers, guide vanes and stage housings

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

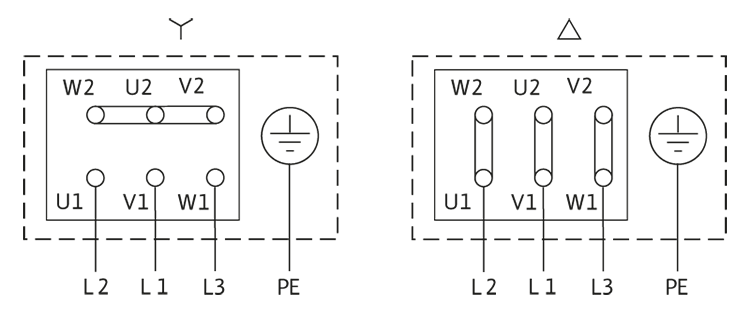

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

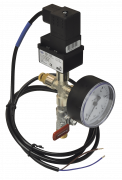

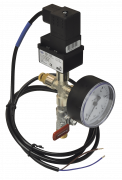

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

Opseg isporuke:

- 1 osnovna ploča

- 4 zavrtnja M12 (uklj. navrtke i podloške) za učvršćivanje pumpe

- 4 zavrtnja M10 (uklj. navrtke i podloške) za učvršćivanje pumpe

- Sigurnosni ventili se isporučuju samo sa fabričkim podešavanjima

- Pritisak aktiviranja: 10 % iznad fabrički podešenog pritiska

- Maks. temperatura fluida: 130 °C

- Pritisak dotoka maks.: 1 MPa

- Maksimalni radni pritisak PN: 1 MPa

- Pritisak produvavanja: 1 MPa

- Priključak na ulazu: R 1, PN10

- Priključak za izlaz: R 1, PN10

- Sigurnosni ventili se isporučuju samo sa fabričkim podešavanjima

- Pritisak aktiviranja: 10 % iznad fabrički podešenog pritiska

- Maks. temperatura fluida: 130 °C

- Pritisak dotoka maks.: 1 MPa

- Maksimalni radni pritisak PN: 1 MPa

- Pritisak produvavanja: 1 MPa

- Priključak na ulazu: R 1, PN10

- Priključak za izlaz: R 1, PN10

Zamenska pumpa List sa zamenskim informacijama

Komentar

Informacije o proizvodu

Helix V 1605-1/16/E/S/400-50

Your advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections.

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

- Corrosion-resistant impellers, guide vanes and stage housings

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

- Electrical connection:

- 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- 1~ 230 V (±10 %), 50 Hz, only Wilo-Helix V 2, 4, 6, 10

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Max. inlet pressure of 10 bar

- Protection class: IP 55

- Max. ambient temperature: -15 °C – +50 °C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, IE4 motor efficiency class, VdS certified Wilo-Helix pumps, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

Bypass kit for continuous ventilation of Helix pumps in series 2/ 4 / 6 / 10 / 16.

- Comes with pressure gauge.

- Suitable to use for all types of self and normal suction systems, e.g. irrigation, cooling towers etc.

Opseg isporuke:

- 1 osnovna ploča

- 4 zavrtnja M12 (uklj. navrtke i podloške) za učvršćivanje pumpe

- 4 zavrtnja M10 (uklj. navrtke i podloške) za učvršćivanje pumpe

- Sigurnosni ventili se isporučuju samo sa fabričkim podešavanjima

- Pritisak aktiviranja: 10 % iznad fabrički podešenog pritiska

- Maks. temperatura fluida: 130 °C

- Pritisak dotoka maks.: 1 MPa

- Maksimalni radni pritisak PN: 1 MPa

- Pritisak produvavanja: 1 MPa

- Priključak na ulazu: R 1, PN10

- Priključak za izlaz: R 1, PN10

- Sigurnosni ventili se isporučuju samo sa fabričkim podešavanjima

- Pritisak aktiviranja: 10 % iznad fabrički podešenog pritiska

- Maks. temperatura fluida: 130 °C

- Pritisak dotoka maks.: 1 MPa

- Maksimalni radni pritisak PN: 1 MPa

- Pritisak produvavanja: 1 MPa

- Priključak na ulazu: R 1, PN10

- Priključak za izlaz: R 1, PN10